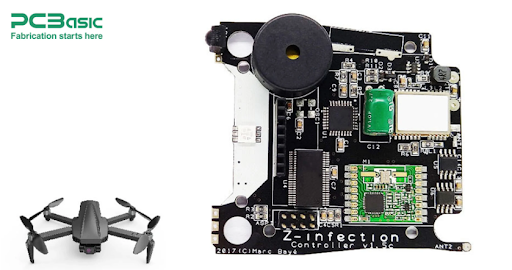

PCBA Solutions for Drones: Explore High-Performance Drone PCBA Services at PCBasic

As drone technology continues to revolutionize industries ranging from aerial photography and agriculture to logistics and defense, the demand for precision-engineered electronics is soaring. At the heart of every high-performance drone lies a sophisticated Printed Circuit Board Assembly (PCBA) — the nerve center that controls navigation, communication, power distribution, and more.

At PCBasic, we specialize in delivering custom drone PCBA solutions that meet the unique demands of aerial systems. With 15+ years of manufacturing expertise and state-of-the-art facilities in Shenzhen and Huizhou, PCBasic is your trusted partner for drone electronics assembly.

Why Drones Require Specialized PCBA Solutions

Unlike standard electronics, drone systems must operate under dynamic conditions such as rapid altitude changes, electromagnetic interference, and high vibration. This requires PCBA solutions that ensure:

- High reliability and lightweight design

- Efficient power distribution for motors and sensors

- Real-time data processing for flight control and navigation

- Durability under thermal and mechanical stress

To meet these needs, drone PCBA must be built with specialized materials, controlled impedance, multilayer structures, and robust quality testing.

PCBasic’s Drone PCBA Capabilities

At PCBasic, we offer end-to-end PCBA services for drone applications, from layout optimization to full assembly and testing:

- Multilayer PCB Manufacturing

- Up to 16 layers

- High-Tg and halogen-free materials

- Copper thickness up to 4oz for power circuits

- Surface Mount & Through-Hole Assembly

- Precision SMT for microcontrollers, GPS chips, gyros, ESCs

- DIP assembly for connectors, battery interfaces, etc.

- Quality Control & Testing

- 100% AOI, X-ray, and functional testing

- Flying probe test for prototypes and small batches

- Turnkey Solutions

- Component sourcing from authorized distributors

- Rapid prototyping and batch production

- Conformal coating for moisture and dust protection

Drone Applications We Support

PCBasic provides PCBA for a variety of UAV types and functions, including:

- Consumer drones (camera stabilization, GPS control, battery management)

- Agricultural drones (sprayer control, route automation)

- Industrial drones (thermal imaging, surveying, payload delivery)

- Defense drones (encrypted communication, autonomous navigation)

Our engineering team collaborates closely with clients to ensure optimal layout design and reliability — whether you’re building hobbyist drones or industrial UAV fleets.

Why Choose PCBasic for Drone PCBA?

✅ Dedicated R&D support – We assist with schematic and layout reviews to ensure flight-critical reliability.

✅ Fast turnaround times – Rapid prototyping and flexible manufacturing for small to mid-volume orders.

✅ Certified quality – ISO 9001, ISO 14001, ISO 45001 certified; IPC Class 2/3 compliance.

✅ Global shipping – Seamless logistics and export support for global drone manufacturers.

Keep an eye for more latest news & updates on The Report!